Fabrication Services

With a state of the art 70,000 square foot fabrication facility, Ansgar subsidiary, Scott Process Systems, Inc., is one of the most technically capable and automated pipe fabrication facilities in the country. Through the use of computerization, automation, and proprietary production processes, we have garnered a reputation for safely delivering products of the highest quality, on time and on budget.

Pipe Spools

We have extensive experience in process, power, and nuclear piping systems fabrication and pre-assembly, including design, constructibility, procurement, project management, and scheduling. SPSI is capable of producing 6,000+ spools per month.

Material Management

We understand the importance of our customers having access to project information throughout fabrication and construction. SPSI is able to provide our clients with enhanced visibility into operations from procurement through delivery and every step in between.

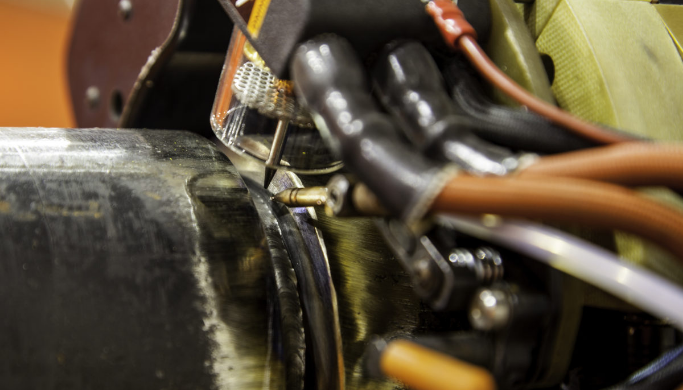

Capabilities

- 1/4” up to 80” pipe diameters with wall thickness of 6”+

- Post-weld heat treating capabilities

- In-house Non Destructive Examination (NDE)

- Material and spool tracking using barcoding, near field, and FPS RFID systems.

- State of the art machine welding and cutting

- Positive Materials Identification (PMI)

- Facility strategically located to handle the most complex projects.